I’m getting ready to saw very soon. I have such an old and filthy pile of wood.

Nope, not me. First thing is first, start with a decent set of clamps. Are you with me?

Here’s a clue to what I’m making and these are like $5 a pair. What can I say. You don’t want to move, then you don’t want to move!

I have other saws but I just grabbed these. The cross it with the smaller teeth was bent and it bound up the in the need several times. That other saw is a little less than a rip and cut fairly decent. I only had one angled error cut on the first cut with the bent cross it blade. I really had to strike that blade down hard on the wood. The others went much easier all though they me stud was much denser than the others. I was able to get such a good stroke I could cut from end to end with the blade without a slippage.

Those boards on top of those two rusted old metal sawhorses are actually nailed on. Not the best setup but I used a “Stud” stud technique. Propping one thigh up under the board. Smooth cuts except towards the very end where I couldn’t cut or support well the very small lazy connective piece, it cause some splintering.

These work well if you set the brace teeth into the wood. They feel easy to topple over but hold direct weight down on them. I could just hit a few skinny nails in if I feel lazy. But I have lots more old scrap 2x4. I was going to buy screws but I can dig through some old metal ammo boxes to find whatever will hold them.

At least the main pieces are done for today. My gray shirt looks like a cow pattern I am so drenched in sweat.

Chop saw would have so much easier. I think I will do just a little more on this. I have some ideas.

I would really like to make my own tools or at least know them so well I could repair them like this.

I tried painting with this Behr paint can I had. This is a two in one paint & primer. It didn’t come out well. I just did a first coat and it seemed to absorb and hardly cover anything. Since I painted over cardboard some stuck and when I removed the cardboard how I have unfinished spots. Maybe because I did it late evening and maybe because it was out of consistency when first opened. After a good initial stirring the consistency stayed thick after reopening. I’m trying to see how much I can heal the wood with paint. There seems to be some exchange like water being forced out of the wood and the paint being sucked in.

But oddly I keep finding these dark stains come out like somebody spit chewing tobacco on my painted wood when I slept.

I might do a second coat and I am getting better with this stuff like working an ice cream station. It’s like thick milk but oddly smells likes fish. Maybe it causes hallucinations despite wearing a mask, but even the brush seemed like a fish tail after a few strokes.

I took the slats from that iron frame bench and sanded them. They are surprisingly strong for being so weathered. The sandpaper sounds intimidating.

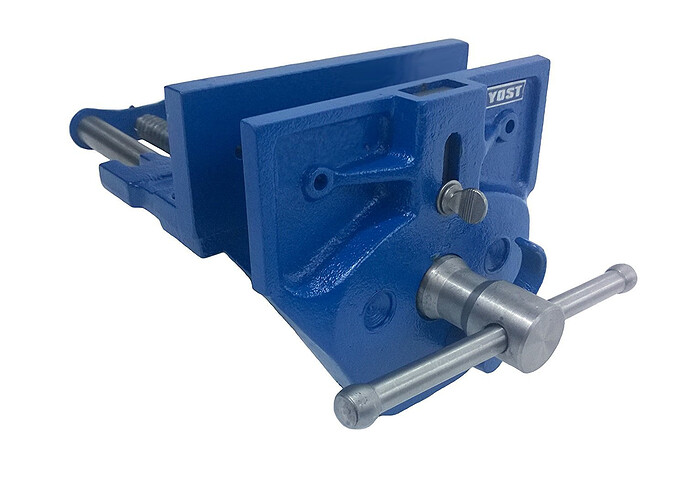

I bought a new woodworking vise yesterday. I had come across a heavy duty antique woodworking vise someone was selling for $60 and thought about how handy it could be but after weighing the time involved to refurbish it I decided to to look at new ones. I found a good deal of one that is even bigger and has a quick release. I couldn’t tell you how many times I have had to spend time figuring out ways to hold a project with clamps and such to complete a step, this will be nice.

Mine is 10" wide, has a 15" opening and weighs 40 lbs.

Certainly makes work more appealing when the material or item is secured in place.

Tychicus, does this add up correctly? This plus this equals hand router? It is this just for uniform depth in drilling?

Just unscrew the small cap/thread guard and screw on and adjust the wing nut.

That is going to require a huge heavy table.

Are you going to bolt it down or just rely on the weight for stabilization?

Do you need mobility for that?

The vise mounts under your benchtop and typically you want it up flush with the top side. The workbench it is going on is 4’x8’ with a one-inch thick top. I will probably be using 4 – 5/16 x 3” lag bolts and will have to use blocking to space it down under the top and will have to cut a hole through my apron under the top. It doesn’t get here until Thursday, I’ll post a pic when I get it installed probably next weekend.

Cool.

Required some blocking and a hole for the bars.

Lag bolted up to the blocking:

This thing is a beast of a clamp. This is table its mounted on:

I’m really glad I purchased a new one, big one and that it has the quick release, after trying it out I would never want to have to spin the handle to open and shut the vise.

Yes. I had envisioned a long heavy table like that when I saw the vice, now I understand the under mount.

Too bad it wouldn’t spin like lug nut cross wrench. I hope it’s just as tight with those teeth. A screw seems analog while those teeth seem digital.

Does it have to tighten or loosen in set increments? Like 2 mm? With a screw you can tighten or loosen like a micrometer depending on how sensitive your arm is.